What Modern Manufacturing Looks Like Through Images

As president and CEO of the NC Chamber, I can say firsthand that our annual ‘Coolest Thing Made in NC’ competition gives me and my staff a great sense of pride—it is an honor to applaud the accomplishments of an extremely innovative industry and the 200+ manufacturing members we represent.

What began in the 1880s as a few textile mills across North Carolina’s landscape has evolved into an impressive, technologically driven industry that generates nearly one-fifth of the gross state product and employs more than 1 in 10 of the state’s workforce. What’s made in North Carolina really does make North Carolina.

In honor of this year’s National Manufacturing Day, we asked our members to show us what modern manufacturing looks like—through photos. We hope you’ll take a look below and see just a few examples of some incredible manufacturing operations in NC!

Gary Salamido,

President & CEO

NC Chamber

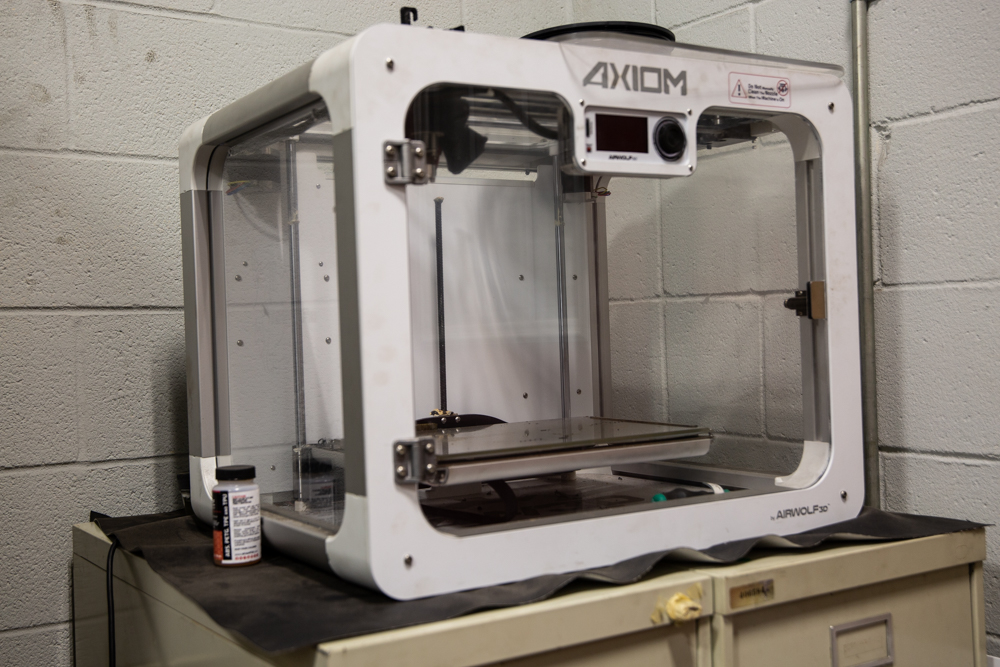

Council Tool Company (Cornerstone member): “We are a family owned fifth-generation manufacturing company in Lake Waccamaw, NC, and we have operated continuously since 1886. We have two robotic grinding cells that we use to do initial grinding of our axes and sledges. This makes the final hand sharpening much easier on our craftsmen. We have recently added a double spindle CNC lathe, tended by a cobot. This means that the lathe will be loaded and unloaded by a cobot (Fun fact: The cobot is a robotic device intended to work around people. If you bump into the cobot, it stops.) Our robots and cobots will not replace our staff but free them up for more of the hand finish work that these bots can’t accomplish. We also have a 3D printer that allows us to see what new products will look and feel like before final production.”

EGGER Wood Products (Cornerstone member): “Completed in March of 2023, our wood recycling facility takes used waste wood, collected by our sister-company Timberpak in Charlotte, NC, and crushes the wood into chips appropriately sized for particleboard production. As the used wood is being crushed to size, any foreign materials, like stones, metals or plastics, are removed using a variety of processes. The ContiRoll® is the heart of particleboard production. This 144-foot-long press uses extreme heat and pressure to create particleboard panels from resin infused wood chips. EGGER’s interior design surfaces are created when resin-soaked décor papers are fused to a particleboard substrate using heat and pressure provided by a short cycle press. The resulting thermally fused laminate (TFL) panels, sustainably produced, can feature solid colors, material reproductions, and even Feelwood decors, embossed-in-register wood reproductions featuring the look and feel of the real thing. However, TFL panels provide greater durability, resistance to fading, and scratch resistance compared to real wood.”

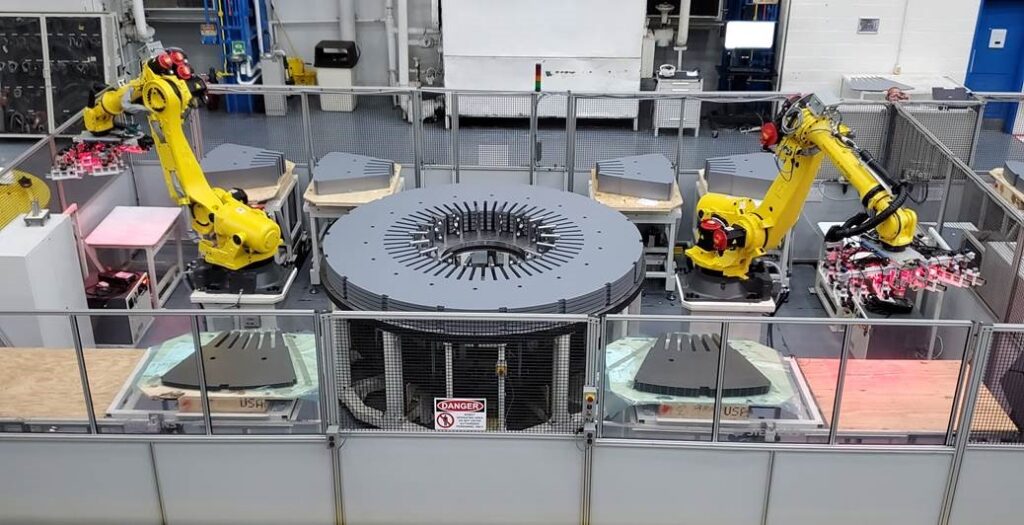

Siemens Energy (Cornerstone member)

In Charlotte, Siemens Energy makes power generation equipment including gas turbines, steam turbines, and generators. Each generator stator core is made up of thousands of individual stacked laminated sheets. The process for stacking these sheets into manageable “packs or donuts” is performed by robots. Custom numerical controlled (NC) programs are created for each core design to stack laminations two at a time to complete a 6” tall pack or donut. On our largest units including nuclear units there are between 150,000 – 250,000 laminations in a complete core. The robotic equipment and tooling are designed to hold nominal core design dimensions to within .005” which is close to the thickness of a sheet of paper. Multiple visual inspections and measurements are performed by an operator before during and after robot stacking operations to ensure quality.

Alamance Community College (Non-member): “[This is our] mechatronics/industrial systems lab at Alamance Community College. We work closely with the local industry to provide training for incumbent workers as well as future employees. This specific area specializes in robotics, automation, instrumentation.”